Kişiselleştirilmiş Rozetinizi Her Yaratıcı İhtiyaca Mükemmel Şekilde Uyarlayın

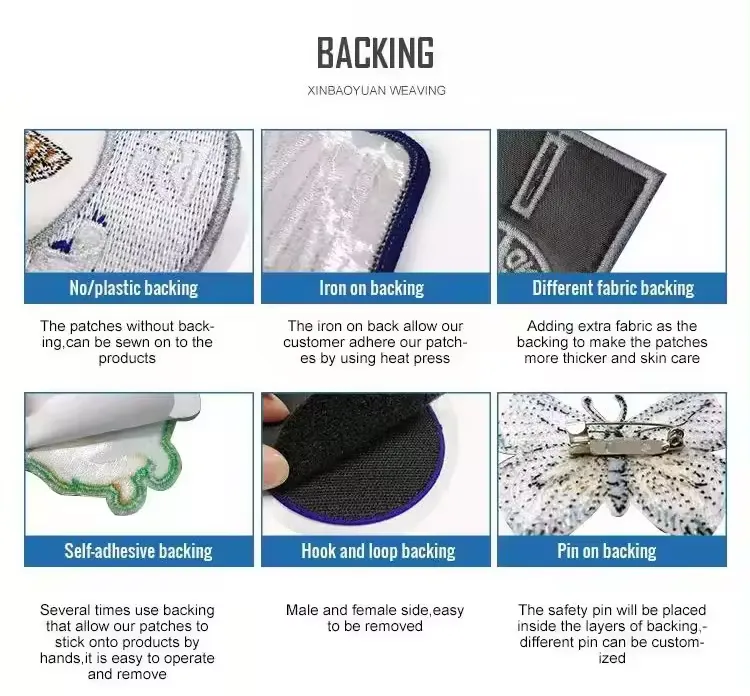

Özel rozet yapım dünyasında, destek tekniği gerçek ruhtur Tasarımın bir parçasıdır; rozetinizin ürününüzle nasıl etkileşime gireceğini belirler. Tekstil sektöründe on yıllık deneyimle desteklenen XINBAOYUAN ekip, derinlemesine bir döküm sunuyor 6 temel destekleme yöntemi Uygulamanız için en uygun olanı seçmenize yardımcı olmak için.

1. Desteksiz / Plastiksiz Destek

Özellikler: Saf kumaş taban, ultra hafif ve esnek

Avantajları:

✅ Herhangi bir kumaş ürününe doğrudan dikilebilir

✅ Orijinal tekstil dokusunu korur

✅ Çevre dostu ve biyolojik olarak parçalanabilir

En İyisi İçin: Giysiler ve tekstil el sanatları için işlenmiş yamalar

Tasarımcı İpucu: Pamuklu ve keten giysiler için idealdir; zıt iplik renklerinin kullanılması el yapımı görünümü güçlendirir.

2. Ütüyle Yapıştırılan Destek

Çekirdek Teknoloji: Isıyla aktive edilen yapışkan tabaka

Uygulama Adımları:

- Ütüyü 150°C'ye önceden ısıtın

- Yamayı pamuklu bir bezle örtün ve 10-15 saniye bastırın

- Soğumaya bırakın ve sıkıca yapıştırın

Test Edilmiş Güç: 50+ kez makinede yıkamaya dayanıklıdır, soyulma olmaz.

3. Kalın Kumaş Destek

Yenilik: Çift katmanlı kompozit yapı

- Üst Katman: İşlemeli tasarım

- Alt Katman: Cilt dostu fırçalanmış pamuk

Kullanıcı Deneyimi:

• Bebek yumuşaklığında dokunuş (OEKO-TEX sertifikalı)

• 300% daha kalın, ancak esnekliğini koruyor

• Metal rozetlerden kaynaklanan rahatsızlığı ortadan kaldırmak için mükemmel çözüm

4. Kendinden Yapışkanlı Destek

Teknoloji Öne Çıkanları: Patentli yeniden kullanılabilir yapıştırıcı

Laboratuvar Testli Performans:

(Gelişmiş güvenilirlik için mevcutsa buraya veri ekleyin)

Kullanım Sıklığı Yapışma Tutma Oranı

5. Kullanım 92%

10. Kullanım 78%

Uygulama Senaryoları: Sergi rozetleri, Geçici etkinlik kimliği

5. Cırt Cırtlı Sistem (Cırt Cırtlı Destek)

Askeri Düzeyde Mühendislik:

• Kanca Tarafı (Erkek): Yüksek mukavemetli naylon kancalar

• Döngü Tarafı (Dişi): Karışımlı yün ilmek kumaş

Avantajları:

▸ 1 saniyede anında takın veya çıkarın

▸ 50kg/cm²'ye kadar çekme kuvvetine dayanıklıdır

Endüstri Kullanım Örnekleri: Askeri ve polis amblemleri, değiştirilebilir spor takımı amblemleri

6. Pin-On Destek

Hassas İşçilik:

Yüzey Nakışı>>>Çizilmez Metal Ara Katman>>>Gizli Pim ve İğne Tasarımı>>>Özel Emniyet Tokası

Yüzey Nakışı

- Seçenekler arasında süslü gravürlü eski pirinç pimler de bulunmaktadır

- Kayıp önleyici döner emniyet kilitleri

- Gizli manyetik çıtçıtlar mevcuttur

Destek Seçim Karar Kılavuzu

| Gereksinim Senaryoları | Önerilen Destekler | Maliyet Endeksi |

|---|---|---|

| Kalıcı Giyim Dekorasyonu | Dikili Destek | ★☆☆☆☆ |

| Hızlı Toplu Uygulama | Isı Transferi | ★★☆☆☆ |

| Çocuk Ürünleri | Kalınlaştırılmış Deri – Dostu Destek | ★★★☆☆ |

| Geçici Etkinlikler | Kendinden yapışkanlı arka yüzey | ★★☆☆☆ |

| Sık Değiştirme | Cırt cırtlı | ★★★☆☆ |

| Üst Düzey Koleksiyon Ürünleri | Özel Broş | ★★★★☆ |

Sektör İçgörüsü:

En iyi lüks markalar genellikle bir "kompozit destek" tekniği—Cilt dostu taban ile sıcakta eriyen yapıştırıcı arasına eğilmeyi önleyici bir file katman eklenmesi. Bu, maliyetleri 40% kadar artırsa da, kenar kıvrılmasını tamamen önler.

Tasarım yapıyor olmanızın bir önemi yok spor takımı rozetleri, şirket logoları veya yaratıcı kültürel ürünler, paylaş kullanım senaryosu (kumaş türü + çevre gereksinimleri dahil) ve biz sağlayacağız fiziksel numunelerle üç özelleştirilmiş destek çözümü!

Özel ihtiyaçlarınızı bize bildirin, rozet vizyonunuzu profesyonel düzeyde sonuçlarla hayata geçirmenize yardımcı olalım.