In the ever-evolving world of fashion, personalization, and promotional merchandise, print patches are gaining momentum as a practical and visually appealing solution. Whether you’re looking to add custom artwork to clothing, promote a brand, or create collectible merch, print patches offer a versatile and cost-effective alternative to traditional embroidered or woven designs.

This in-depth guide explores what print patches are, how they compare to other patch types, the different printing techniques available, and how to use them effectively for style, branding, and functionality.

What Are Print Patches?

Print patches are decorative or functional patches where the design is applied using printing methods instead of stitching. Unlike embroidered patches that use threads to create an image, print patches rely on modern print technologies to produce detailed, colorful, and sometimes photo-realistic designs.

They can be applied to a variety of base materials, including fabric, leather, PVC, silicone, and felt, and are often used in fashion apparel, team gear, promotional items, and collectible art pieces.

Why Choose Print Patches?

There are several key benefits that make print patches a smart choice:

✔ High-Resolution Design

Printed patches can capture intricate artwork, gradients, fine lines, and even photographic details—something embroidery often struggles with.

✔ Cost-Effective for Complex Art

Designs with many colors or complex details are more affordable to reproduce with printing than with stitching.

✔ Fast Turnaround

Since printing is a quicker process than digitizing embroidery files and setting up thread runs, you can get large quantities of print patches produced in less time.

✔ Lightweight & Flexible

Print patches are generally thinner and more flexible, making them ideal for lightweight garments or sportswear where comfort is key.

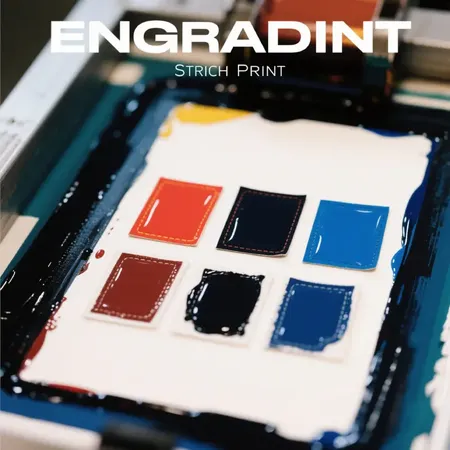

Common Printing Techniques for Patches

There are several methods used to create high-quality print patches, each with its own advantages:

1. Sublimation Printing

Perfect for polyester-based patch fabrics, sublimation uses heat to infuse dye directly into the material. It results in vibrant, long-lasting color and is ideal for sports patches or high-res artwork.

2. Screen Printing

A traditional method that uses ink pushed through a stencil screen onto the patch surface. Screen-printed patches are durable and ideal for bold, simple graphics.

3. UV Printing

UV printing allows for direct-to-surface printing with incredible detail, even on PVC or rubber patches. Great for high-end or novelty items.

4. DTF (Direct-to-Film)

A rising trend in custom patches, DTF allows highly detailed prints to be transferred via a film carrier. It’s flexible, versatile, and works on many surfaces.

Ideal Uses for Print Patches

Print patches can be used across a wide range of industries and purposes:

- Custom Apparel: Add logos or artwork to jackets, hoodies, and hats

- Brand Merch: Create unique, eye-catching patches for giveaways or sales

- Team Uniforms: Sports teams or clubs often prefer print patches for detailed logos

- Event Memorabilia: Concerts, festivals, and conventions often use print patches as limited-edition souvenirs

- DIY Fashion: Streetwear fans love adding printed patches to personalize denim, bags, and caps

How to Apply Print Patches

Depending on the backing, print patches can be applied in different ways:

🔸 재봉하기

Offers the most secure and permanent option, especially for jackets, bags, or workwear.

🔸 다림질 가능

Many printed patches come with heat-activated backing for quick, easy application on cotton or polyester fabrics.

🔸 Velcro

Ideal for tactical gear or clothing that requires interchangeable patches.

🔸 Peel-and-Stick

Temporary but great for one-day events, photoshoots, or test layouts.

전문가 팁: Always follow the manufacturer’s instructions for best adhesion and wash durability.

Tips for Designing Custom Print Patches

Creating effective and visually appealing print patches requires thoughtful design. Here are a few tips to guide the process:

- Use Vector Art or High-Res Images: Printing captures detail, so avoid blurry or low-quality files.

- Be Bold with Color: Since print patches can handle gradients and full-color tones, take advantage of that!

- Choose the Right Shape: Don’t feel limited to circles or rectangles. Die-cut print patches allow for custom contours and silhouettes.

- 배치에 대해 생각해보세요: Design your patch to fit a specific location—chest, sleeve, hat, bag, etc.—for the best visual impact.

Comparing Print Patches to Embroidered Patches

| 특징 | Print Patches | Embroidered Patches |

|---|---|---|

| 세부 수준 | High (photo-like possible) | Moderate (limited by thread) |

| 생산 시간 | Faster | 더 느리게 |

| Cost for Complex Art | 낮추다 | Higher |

| 조직 | Flat | Raised/Textured |

| 유연성 | More flexible | Slightly rigid |

Each has its own strengths, but if you’re looking for design versatility and speed, print patches are the way to go.

마지막 생각

Whether you’re creating a custom jacket design, planning merch for your brand, or designing team uniforms, print patches are a smart, stylish, and modern option. With their flexibility, affordability, and creative potential, printed patches open up a world of possibilities for self-expression and branding.

Explore materials, experiment with colors, and bring your vision to life—one printed patch at a time.