In the fast-evolving world of textile decoration, digital techniques and automation dominate many production lines. However, traditional methods like manual press screen printing continue to play a vital role—especially when it comes to high-precision, small-batch, and artistic projects. Often referred to as hand screen printing, this technique is celebrated for its flexibility, tactile quality, and precision in reproducing detailed artwork on fabrics and garment accessories.

If you’re a designer, brand owner, or print enthusiast looking for a reliable way to achieve premium, layered, and textured prints on fabrics, understanding how manual press screen printing works could open a new world of possibilities.

What Is Manual Press Screen Printing?

Manual press screen printing, also known as hand screen printing, is a traditional technique where a design is printed onto fabric using a mesh screen, ink, and a squeegee—entirely by hand. The process takes place on long printing tables (often 20–30 meters in length), where the operator manually aligns each print and pulls the squeegee to transfer ink through the stencil mesh onto the fabric or label material.

Unlike automated machines, this method allows the printer full control over pressure, angle, ink flow, and fabric placement—making it ideal for complex, multi-color designs, special effects (like puff or glitter), or unique substrate materials that automated presses can’t handle well.

The Step-by-Step Process of Manual Screen Printing

Despite its manual nature, manual press screen printing follows a standardized and structured process. Each step is crucial to the final result:

1. Artwork Separation and Film Preparation

The design is first separated into individual color layers. Each color requires its own stencil, typically created by printing the artwork in black on transparent film (known as a “film positive”). These films serve as the templates for screen exposure.

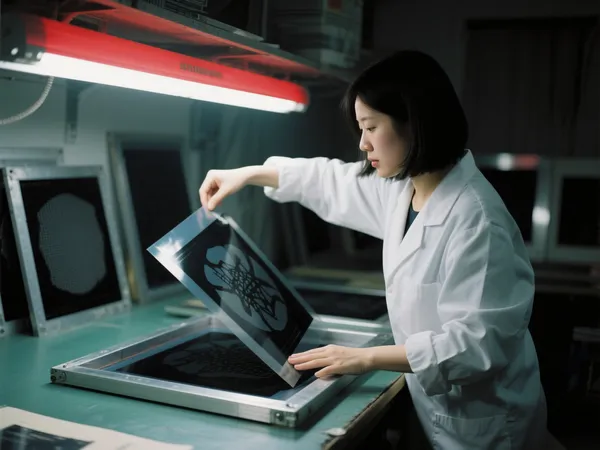

2. Screen Creation (Stencil Making)

Each film is then used to expose a mesh screen coated with a light-sensitive emulsion. When exposed to UV light, the clear areas on the film allow light to pass through, hardening the emulsion, while the black areas block the light, leaving those sections water-soluble. Washing out these areas reveals the stencil—the part of the screen where ink will pass through.

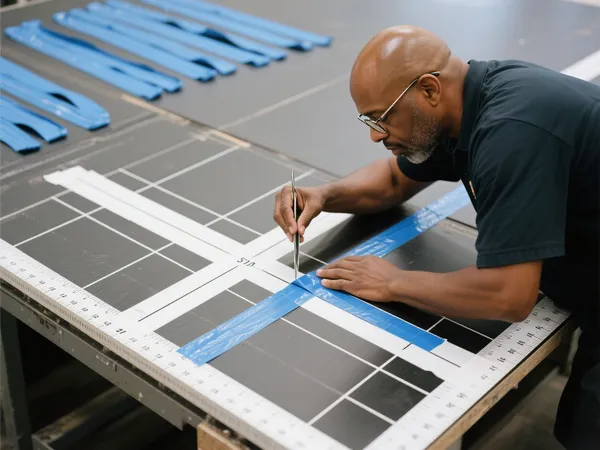

3. Table Registration and Fabric Placement

Precision is key. The printer prepares the printing table using guide tapes, rulers, or alignment marks to ensure every piece of fabric is printed consistently. Accurate registration is essential for multi-color designs, ensuring each layer aligns perfectly without ghosting or misprints.

4. Ink Mixing and Testing

Custom color mixing is often required to match Pantone shades or client branding. Ink viscosity is adjusted based on fabric type and print thickness. For example, thicker inks are used for puff prints or raised logos, while thinner inks flow better for fine-detail prints.

5. Hand Printing Execution

With the screens in place and fabric aligned, the printer pours ink onto the screen, then uses a hand-held squeegee to pull the ink across the stencil area. This step is repeated for each fabric piece and each color layer. High-detail or thick prints may require multiple passes per layer.

Some designs, especially those needing 3D textures or saturated colors, require multiple hand pulls (sometimes 30–50 strokes) to achieve the desired depth and opacity.

6. Drying and Curing

After each layer is printed, the fabric is cured—typically by passing it through a heated tunnel dryer or using heat guns for partial drying. Some production lines implement “print once, dry three times” workflows to enhance ink adhesion, especially for specialty prints.

Unique Advantages of Manual Press Screen Printing

While it may seem outdated compared to automated systems, manual press screen printing offers several distinct benefits:

– Superior Print Precision

Because each item is manually aligned, multi-color prints can be perfectly registered, and the printer can adjust in real-time to ensure color accuracy and sharpness. This is especially valuable in custom fabric printing for fashion brands or labels.

– Ideal for Special Effects

Unlike flat digital prints, manual screen printing allows layered ink applications, creating effects like:

- Puff/3D ink

- Glossy or matte varnishes

- Flocking (raised suede-like textures)

- Glitter or metallic prints

These are difficult—if not impossible—to achieve with digital printers or standard screen-printing machines.

– Material Versatility

Manual screen printing supports a wide range of substrates, including:

- Cotton, canvas, silk, polyester

- Ribbons, woven labels, PU leather

- Jersey fabrics or textured knits

It’s particularly suitable for Bekleidungszubehör, trims, and small-batch experimental orders.

– Lower Setup Costs for Small Batches

Unlike automated presses that require significant setup time and costs, manual printing allows brands to test new designs, produce small runs, or create prototypes without high upfront investment in tooling or machine adjustments.

Application Scenarios

Here are a few real-world examples where manual screen printing truly shines:

- Logo printing on garment labels for luxury clothing lines

- Embossed satin woven labels using thick ink to simulate a padded effect

- Eco-friendly water-based ink printing for export orders with strict environmental standards

- Custom ribbon or webbing prints for designer bags or high-end packaging

Abschließende Gedanken

Manual press screen printing is more than just a technique—it’s a craft that blends technical skill with artistic sensibility. In an era where automation often dominates, the nuanced control and richness of hand printing continue to attract designers, boutique brands, and fabric enthusiasts alike.

If you’re looking to print detailed, textured, or high-end designs on various fabrics, manual press screen printing remains one of the most trusted and flexible methods available. Whether you’re exploring custom fabric printing for your next product launch or need small-batch runs with premium quality, the hands-on approach of this traditional craft might be exactly what you need.

By combining modern materials with time-tested skills, hand screen printing keeps tradition alive—one stroke at a time.